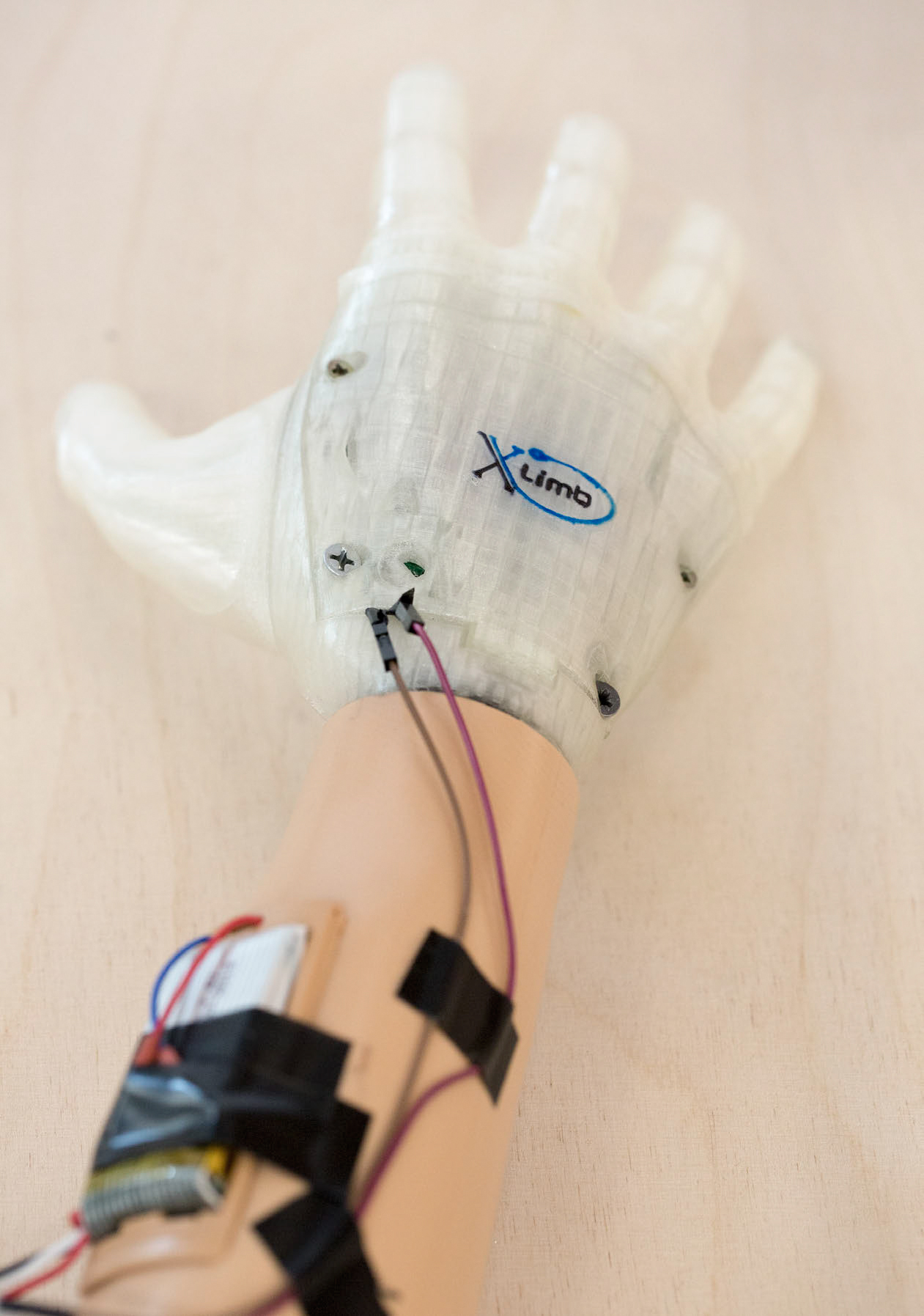

3D Printed Soft Robotic Prosthetic Hand

_

Alireza Mohammadi, Jim Lavranos, Peter Choong + Denny Oetomo, School of Electrical, Mechanical and Infrastructure Engineering, University of Melbourne

The loss of an upper limb severely affects the ability to execute daily tasks and it occurs to people of any age, including those in the prime of their lives and some even from birth. Replacement of an upper limb with a functional prosthetic hand has the potential to return some of the limb functionality. Design of prosthetic hand for children is challenging due to small size and constant growth of their hand. We have designed an anthropomorphic light-weight soft robotic prosthetic hand for adults using 3D printing of compliant materials. The objective of this research is to develop this design to accommodate children with upper limb loss.

The design of the prosthetic hand is conducted with a focus on low complexity and user-friendly interface, to allow intuitive, robust, and reliable controlin in addition to its lightweight quality. This is done by first focusing on providing only the most common grasps for the activities in daily living and second, using 3D printing techniques to manufacture the overall hand with low infill in the structure to reduce the weight. We have realised the two most commonly used grasps: pinch grasp and power grasp. Combined, these grasps will cover more than 70% of the daily activities. For fabrication of the whole hand, we used a commercially available 3D printer to fabricate the parts. The hand for children has one motor which pulls five cables, each corresponding to a finger. Using the different size of spools for pulling tendon cables of each finger, the hand can provide pinch and power grasp. The overall weight of the hand, including the controller and actuator is less than 200 gram. Due to the parametrised CAD of the hand, the dimensions of the hand can be readily customised for different hand sizes. The hand is controlled using two electromyography (EMG) electrodes for opening and closing of the hand. Compliance of the hand enables users to grasp a wide range of objects in one specific pre-shape hand - eliminating the need for switching between different grasps. The designed hand is ultra-light, durable, cheap and easy to manufacture. It is readily customisable for different hand size due to parameterised CAD design and using 3D printing techniques. The proposed design addressed the challenges in the design of prosthetic hand for children due to their small size and constant growth.

_

Alireza Mohammadi_ is currently a Postdoctoral Research Fellow with the University of Melbourne, performing research on robotic surgery and control of mobile robots

Jim Lavranos_ is the Senior Clinical Prosthetist at Caulfield Hospital. He has worked in both public and private facilities around Australia dealing with both adult and paediatric clients with all levels of amputation.

Peter Choong_ is the Sir Hugh Devine Professor of Surgery, and Head of Department of Surgery University of Melbourne at St. Vincent’s Hospital Melbourne.

Denny Oetomo_ was a Postdoctoral Research Fellow at Monash University (2004-2006), INRIA Sophia Antipolis (2006-2007), and joined the University of Melbourne, Melbourne, Australia, in 2008, where he is currently an Associate Professor.

Image: 3d-printed paediatric soft bionic hand.