Rose: A ReDesigner

The job of ReDesigning grew out of changes late last century, when manufacturers in Europe and Japan (and later in most industrialised countries) were compelled to take back their products at the end of their life.

Led by Xerox and others, this quickly led to a new manufacturing strategy in which products were taken back and components recovered, refurbished and reused in future products. (Australian analysis of the Xerox system at the turn of the Century found that their re-manufacturing system reduced waste by over 75% and resource use by similar amounts.)

Over time, companies became very confident in predicting the ’second-life’ (and third, forth ..life) of these components. Design approaches for both products and components changed to ensure maximum reuse and longevity of components (maximising the value of components at the end of their ‘first-life)’.

In order to optimise the process of recovery, refurbishment and reuse, Xerox and other large manufacturers changed their business strategy from the sales of office machines to the ’service of printing/copying’ documents, a service delivered through their machines which remained the property of the producer. Whether these machines were 100% new (in terms of their component parts) or 50% reused (or whatever percentage) was of no concern to the user as long as their document service was maintained as per their contract. This approach was quickly adopted by leading companies in Australia, across all sectors (starting in the early 2000’s with a large office-systems furniture company and several local domestic appliance manufacturers). This form of ‘closed-loop’ manufacturing reduced waste to landfill by 75-90% and delivered a similar level of reduction in resource inputs.

As companies up-graded products (and as some products and even companies disappeared altogether from the market) a new global market for new-used components from ‘orphaned’ products began to grow.

At first, low-volume local products were ‘redesigned’ from components scavenged from mass-produced products, existing almost as a parasitic industry developed by designer-makers. From this activity a global ‘open source’ support network quickly developed to trade components and designs. A community of people who exchanged information about product inventions based on the re-combination of new-used mass-produced components and local low-volume (locally-produced) components and sub-assemblies soon evolved into a mainstream design business. Educational programs in universities adapted their curricula to support such work.

Large companies recognised the opportunities to sell unwanted new-used components (saving waste charges in the process) and set up more sophisticated internet databases and exchanges. The sector has grown into a mature ‘local customised product’ (LCP) industry.

The skills and practice of re-designers has greatly contributed to the overall success of ‘recombinant’ eco-innovation in Australia. Many systems developed around some specific local need have later become ‘mainstream’ innovations picked up by Australian and international companies.

Career and life

- Trained as an industrial re-designer.

- Enjoys the low-tech/high-tech integration available within the district and the access to a close knit community.

- Lives and works in a prefab home on Keith’s fathers property which she pays rent for land access.

- Enjoys tending the garden and supervising children in the neighbourhoods childcare facility during the day and an active social life around Melbourne at night.

- In her work-leisure activity she grows and trades snails for a Victorian producer-restaurant network, paying the local children to collect snails from the local gardens9which she uses to breed stock).

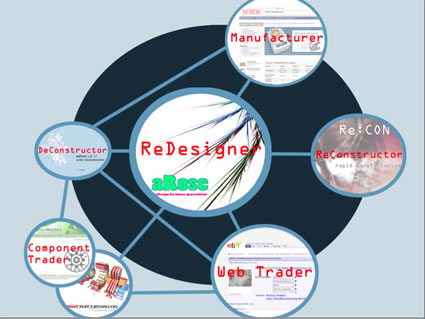

- Works the equivalent of 3 days per week in a highly integrated virtual network. Uses the facilities of the local fabrication plant as a practical workshop to develop and produce LCP’s. She has no specific work schedule as so much of her design practice is based internationally as part of an open-systems community. With global time zones she has completely lost the traditional 9 – 5 mentality.

- Her Redesign practice draws on both the top-down and bottom-up drivers for reusability. Top-down implying the notion of assisting manufacturers in their initial design process to produce multiple use components, modularity, design-for-deconstruction, recycling and personalization. Bottom-up redesign involves the development of new local products suited to small run production (using the local flexible manufacturing facility).

- Her practice provides manufacturers with extended component life reducing the number of parts entering the waste stream which reduces their carbon taxes.

- Uses web traders to source components and a network of de-constructors and new-used component warehouses. She purchases many small batches of components from the component trading section of e-bay (still the largest of its kind) or many of the smaller specialised auction sites.

The ‘Rose: a Re-Designer’ vision was developed as part of the VEIL 2007 Workshops by Mark Richardson.