As you walk up through the building, you will have noticed that the stairs are designed using different dimensions. Which ones feel best to walk up and down?

The Concept

The Y Stair, a central vertical pathway from the First Floor to Level Four, offers users a variety of options as they move through the building.

The Y stair is based on a conventional series of straight run stairs, but at each mid landing the stair splits, allowing the user to choose alternate routes to shorten their path to a given destination. Designed as a prefabricated steel truss system, the Y-stair provides a clear span across the Atrium. The internal faces of the stair are lined in timber, while the external vertical surfaces are treated with acoustic lining. The underside exposes the steel truss, providing opportunities for learning around materials and processes.

Installation of Y Stair Frames

The structural steel frames of the Y Stairs were all prefabricated offsite by Aus Iron Industries. The frames used steel square hollow section tubes that were prefabricated using computer modelling.

Brackets were installed on the concrete frame of the building onsite to support the stairs.

The frames were transported to the building site and carefully lifted in so that they sat at the correct angle – this involved complex calculations. A tower crane was used to lift the frame into position.

Watch video footage of the installation below:

Finishing the Y Stair

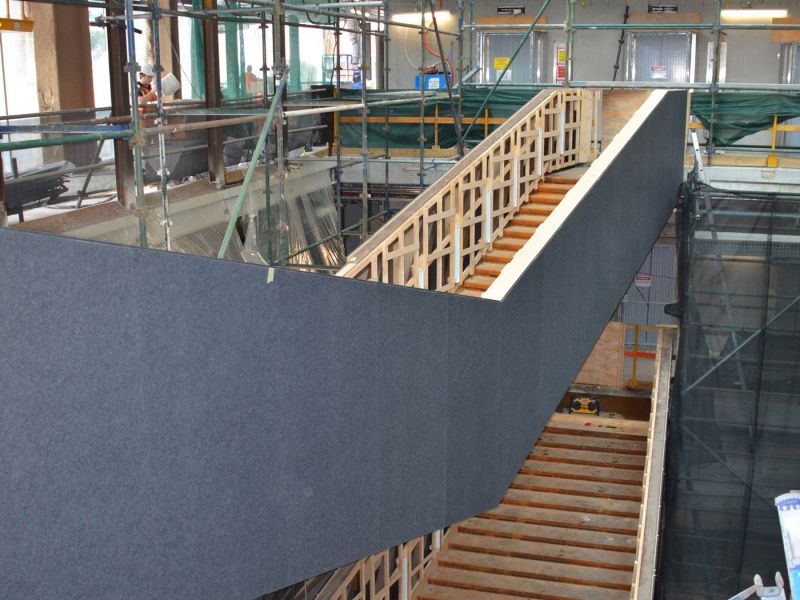

After installation, the size of the staircase was then framed out with timber on both sides to accommodate the acoustic linings and interior finishes.

On the outside, the first layer comprised perforated MDF board which was then covered with charcoal-coloured acoustic material. On the inside, Victorian Ash veneered board was used for the lining.

The steel stair treads were then covered with 20mm-thick plywood and then covered with tongue-and-grooved timber flooring.

LED lights were installed prior to the internal lining. Stainless steel handrail brackets and stainless steel tube was then installed.